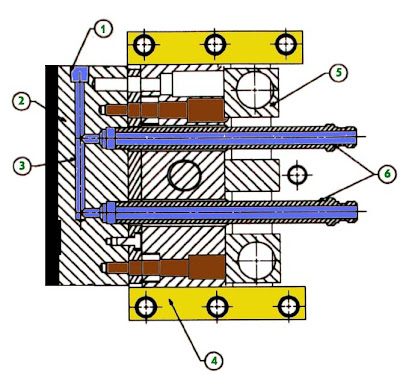

Basic Cooling Layout

in principle, the more uniform temperature in the cavity, the better the resulting product, the more uniform and rapid heat transfer processes during the process of solidification occurs, the faster the cooling process, and of course the faster the cycle time that happened.when designing, to keep the cooling process is rapid and uniform cooling channels should be sought closer to the wall of the product, especially for regions of high and thick walls. therefore the cavity cooling channels is essential.

in the image above, is an example of basic connections cooling layout, its parts are

A. cavity colored with blue

2. green is mold base

3. yellow is cooling joint plug

4. white is hose connection to connecting cooling joint plug

on the left side of mold in above picture, we see that two pcs of cooling joint plug (yellow color) in that side, is for input and output of cooling mold base and cooling channel from the machine.

Rectangle Like Layout

depend one cooling layout is a favorite around the product, because the drilling process should be straight, then the shape is rectangle, except in the form of circular gear will be retained.